Fire Prevention and Protection

Hey guys. Welcome to this video on fire prevention and protection. Today we will be discussing Fire Controls.

There are six big things to be aware of when it comes to fire control:

- Storing flammables and combustibles

- Grounding and bonding

- Building Design

- Controlling and Extinguishing

- Preventing or Reducing the Severity of an Explosion

- Burns

Storing Flammable and Combustible Materials Indoors

When storing flammable or combustible materials indoors, the following actions should be taken:

- Store only small amounts in occupied areas or buildings; larger amounts need to be stored in completely separate facilities.

- Follow National Fire Protection Association (NFPA) standards when designing storerooms for flammable and combustible materials, including standards for ventilation, static electricity grounding systems, explosion-proof light switches and fixtures, self-closing doors with raised sills, signage, and floor contours.

- Follow NFPA standards for storage cabinets designed to hold small quantities of flammable and combustible items.

- When transferring flammables from one container to another, ensure that the containers are touching each other or are connected to a grounding rod or line.

- Store flammable liquids in closed containers.

- When dispensing flammable liquids from drums, use gravity or suction pumps rather than pressurizing the drum.

- Use safety cans to move flammable liquids from their storage area to their point of use.

- Use plunger cans if you need to wet cleaning cloths with a flammable liquid.

- Store cloths that have been contaminated by flammable liquids in a small self-closing container that you empty regularly.

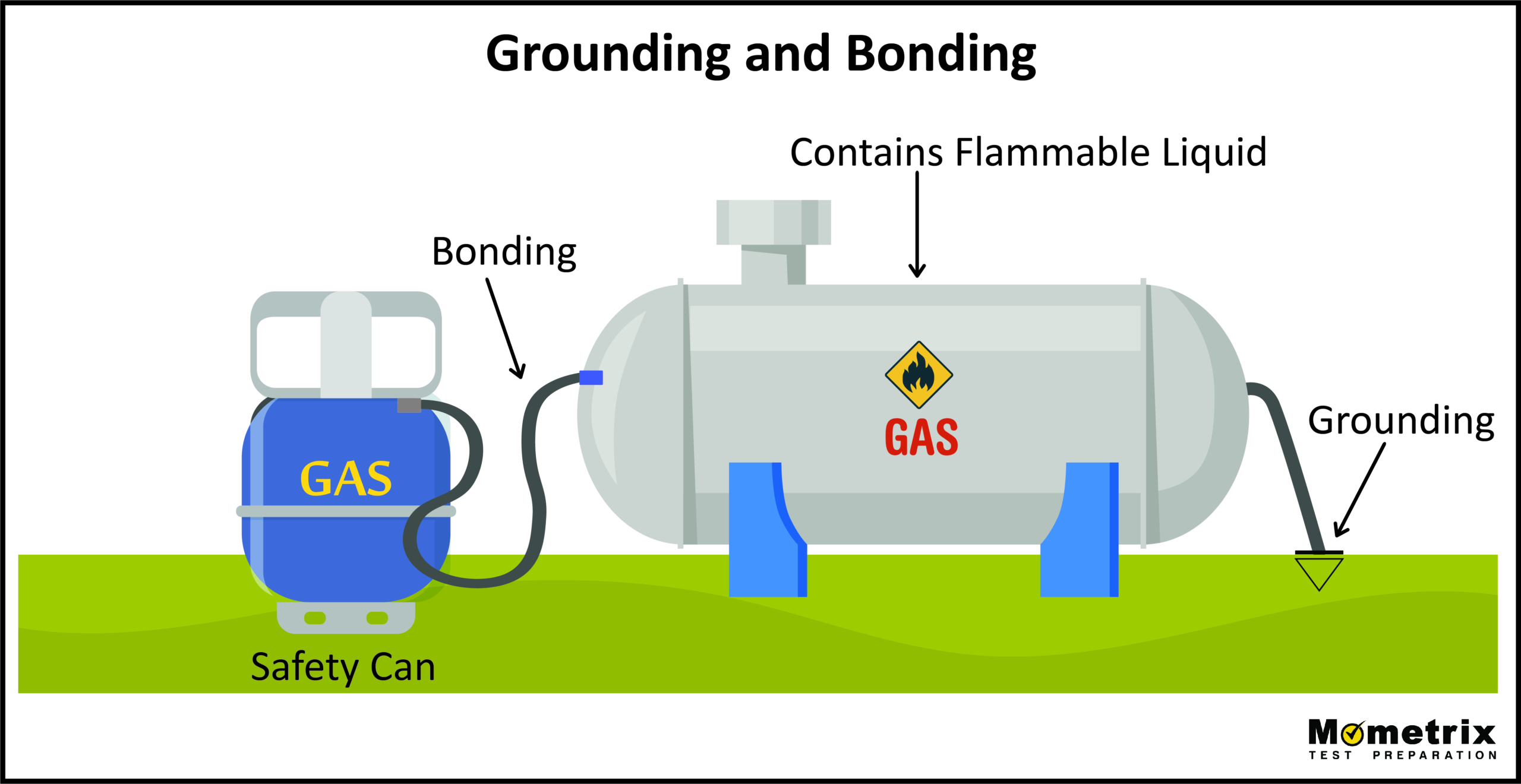

Grounding and bonding for static electricity safety

Static electricity is the buildup of electric charge on an object. It is created when two dissimilar materials are brought into contact, such as when liquids flow through pipes, splash in containers, and are applied to materials. Static electricity can build up over time if there is nowhere for the charge to flow. It could eventually reach a level such that a spark could jump a gap and ignite nearby flammable vapors.

To avoid fires or explosions due to static electricity, metal containers used for storing flammable liquids should be connected to an earth ground. Small containers used to transport flammable liquids (safety cans) should be bonded (electrically connected) to the storage container during filling. When all metal containers are at the same electric potential, there is no possibility of sparks. Any electric charge caused by the transfer of liquids has a safe path back to ground, and will not build up on containers.

Buildings designed for improved fire safety

Fire safety in buildings has three goals:

- Getting occupants of the building out safely.

- Keeping property loss as low as possible.

- Reducing interruption of operations.

For optimal fire safety in buildings, building designers should do the following:

- Ensure that fire equipment can get access to all sides of the building without being blocked by landscaping or parking areas.

- Locate water supplies, hydrants, and valves throughout the building.

- Provide enough space between buildings so that fire cannot jump from one building to another. Include fire walls, fire resistant doors, dampers, and shutters to confine fire, preventing it from moving to other buildings or other parts of the same building.

- Choose building materials with high fire resistance ratings.

Controlling and extinguishing fires

Numerous types of detectors, extinguishers, and alarms are available for controlling and extinguishing fires:

- Heat detectors sense when air temperature becomes too high.

- Smoke detectors use ionization or photoelectricity to sense when smoke is in the air.

- Smoke detectors usually sense fire before heat detectors do because smoke usually occurs before the heat rises significantly.

- Flame detectors m p during fires.

- Portable extinguishers are available in different types for different classes of fire.

- They are small enough to be carried and can be used to put out small fires before they spread.

- Water spray smothers fuel and reduces heat.

- Sprinkler systems, whether water-based or chemical-based, are the most effective for controlling fires in large buildings.

- Fire suppression systems based on carbon dioxide, halons, dry chemicals, and foams are useful for extinguishing fires in areas where water would be hazardous, as with electrical fires or flammable liquids.

Controls for preventing or reducing severity of explosions

The exact controls used to prevent an explosion or reduce the severity of an explosion will change depending on the materials and use environment.

However, some general guidelines include the following:

- Limit the amount of explosive material stored in any one area.

- If large amounts of explosive materials must be stored, they should be in a remote area.

- Regularly clean areas where explosives are stored so dust will not accumulate.

- Eliminate sources of ignition such as lighters, moving belts, and electrical equipment.

- Store fuels and oxidizers in separate locations.

- Install extinguishing and suppression systems to put out fires before an explosion can occur.

- Use vents in any containers where explosive mixtures could lead to explosions.

- Use distance and barriers to separate explosive materials from each other and from populated areas.

- Train anyone handling, using, and distributing explosives.

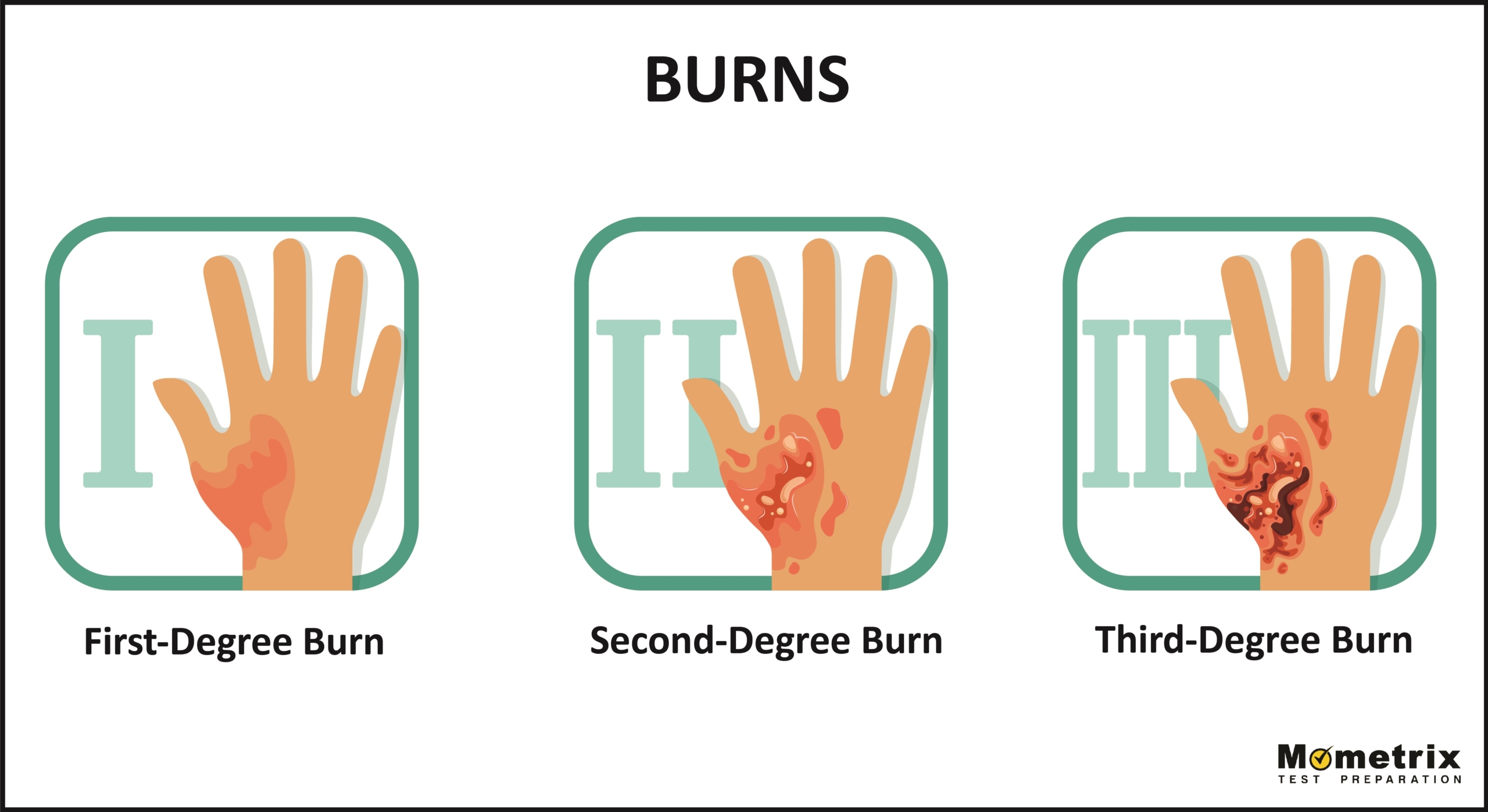

Burns

A burn occurs when heat is applied to body tissues faster than the body can dissipate it. When this happens, the body tissue stores the excess energy, causing the temperature of the tissue to rise and leading to discomfort or pain. The traditional way to classify burns is according to their appearance as first-, second-, or third-degree.

A first-degree burn is superficial with some reddening and pain. Healing takes 5-10 days. A second-degree burn is deep with blisters and pain. Healing can take as long as a month. With a third-degree burn, the skin is destroyed and healing can take many months. There is actually less pain with a third-degree burn. A newer way to classify burns is according to the depth of the tissue that is damaged. According to this classification, burns are considered superficial, deep, or full.

Chemical burns

Most chemical burn injuries occur in the manufacturing industry, service industry, trade, and construction. Chemical burns can be caused by numerous chemicals, including the following:

- Acids and alkalines.

- Soaps and detergents.

- Cleaning compounds.

- Solvents.

- Degreasers.

To prevent chemical burns, a safety program must:

- Educate workers and supervisors about the chemicals they are using.

- Require the correct personal protection equipment for the chemical being used.

- Educate workers and supervisors on how to correctly use and maintain the personal protection equipment.

- Monitor the use of personal protection equipment to ensure that it is being used properly.

- Monitor the use of personal protection equipment to ensure that it is replaced when it passes its useful life.

Heat burns occur most commonly in the manufacturing industry, especially in tasks involving welding and torch cutting. Major causes include Flame, Molten metal, Asphalt and tar, Steam and water.

To reduce the risk of heat burns, a safety program must do the following:

- Include and enforce safety policies and procedures when working with heat hazards.

- Educate workers about heat hazards and about the safety policies and procedures.

- Provide correct personal protection equipment that is in good shape and train workers how to use the equipment properly.

- Ensure that employees have adequate workspace.

- Educate employees on how to use and maintain their tools.

Understanding fire controls can plays a vital role in your safety, and the safety of others.

I hope this video was helpful. Be sure to check out more of our videos here. See you next time!